Ferro silicon magnesium (FeSiMg) is an important casting additive that plays a crucial role in cast iron production. It can act both as a nodulizer and an inoculant, with different functions depending on the application. The dual role of ferro silicon magnesium makes it indispensable in the production of ductile iron (also known as spheroidal graphite iron) and other cast iron products. This article will explore the functions of ferro silicon magnesium as both a nodulizer and an inoculant, as well as its applications in the casting industry.

In cast iron production, the primary function of a nodulizer is to promote the formation of spherical graphite, changing its structure. In the production of ductile iron, the shape and distribution of graphite are critical to the mechanical properties, strength, ductility, and toughness of the castings. When graphite forms as spherical nodules rather than flake-like or tree-like structures, the mechanical properties of the cast iron are significantly improved.

As a nodulizer, ferro silicon magnesium effectively transforms the graphite from flake to spherical form, thereby greatly enhancing the performance of ductile iron. After nodulization, the castings exhibit improved ductility, strength, and surface quality, making them more durable and easier to process. Therefore, ferro silicon magnesium is widely used in the production of ductile iron, especially for industrial products that require high-quality castings, such as automotive parts, machinery components, and construction materials.

In addition to its role as a nodulizer, ferro silicon magnesium also functions as an inoculant. In the casting process, the primary role of an inoculant is to improve the metal’s grain structure, thereby enhancing the mechanical properties of cast iron. Inoculants help control the levels of carbon and silicon in cast iron, optimizing the microstructure and reducing defects such as porosity and cracks during casting.

As an inoculant, ferro silicon magnesium not only adds beneficial alloying elements to the cast iron but also enhances its deoxidizing ability, preventing the formation of oxides and ensuring the quality and stability of the castings. Additionally, ferro silicon magnesium helps improve the mechanical properties of cast iron, particularly in terms of wear resistance and compressive strength. Therefore, ferro silicon magnesium is commonly used in both steel and cast iron production processes, especially in the manufacture of high-quality castings, where it provides an excellent balance of performance and cost-effectiveness.

The dual functions of ferro silicon magnesium as both a nodulizer and an inoculant make it uniquely advantageous in the casting industry. In the production of ductile iron and other cast irons, ferro silicon magnesium enhances the performance and quality of the castings, reduces defects during production, lowers production costs, and improves product competitiveness. Its excellent nodulizing effect and ability to optimize the metal’s microstructure make it widely applicable in various casting processes.

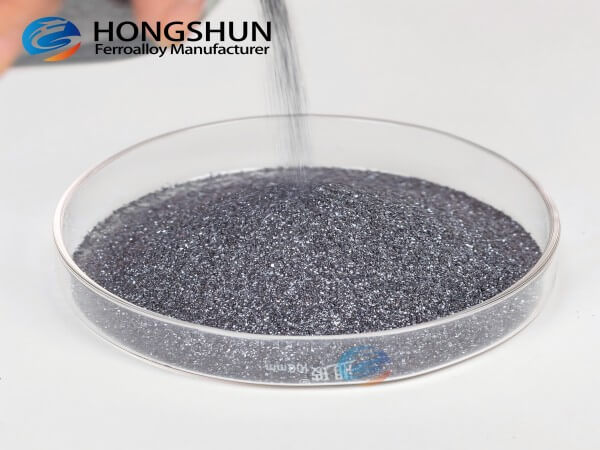

On the market, many specialized ferroalloy suppliers, such as Anyang Hongshun Industrial, offer high-quality ferro silicon magnesium inoculants and nodulizers. As a leading supplier in the industry, Anyang Hongshun Industrial ensures that the products they provide deliver efficient nodulization performance and superior inoculation effects. With continuous technological innovation and product optimization, the company offers customized solutions to meet the specific production needs of different industries, ensuring optimal results for its customers.

In conclusion, ferro silicon magnesium plays an irreplaceable role in improving the quality of steel and cast iron. Whether as a nodulizer or an inoculant, ferro silicon magnesium is essential for optimizing the microstructure of cast iron and enhancing the performance of final products. As casting technologies continue to evolve, the application of ferro silicon magnesium will become even more widespread, further strengthening its position as a key additive in the casting industry.

By selecting the right ferro silicon magnesium products and optimizing the production processes, companies can significantly improve production efficiency and product quality. Choosing the appropriate ferro silicon magnesium additive not only lowers production costs but also provides a competitive advantage in the market.

Copyright © 2024 TIME INTERNATIONAL DMCC All Rights Reserved. XML

Scan

Scan